Rad-Flex™

Technology / Rad-Flex

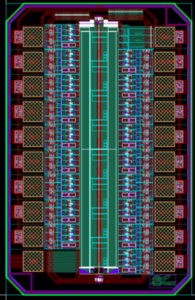

Rad-Flex™ Logic

Rad-Flex™ is an evolution in semi-custom RHA logic products. It is our unique ability to rapidly develop logic devices from our already existing rad-hard assured silicon substrates.

Benefits include:

- Cost-effective development of semi-custom logic devices

- Assured cost reduction over up-screening

- Rapid delivery: 3 months for EM parts; 6 months for flight-ready parts

- Most standard or custom logic functions can be implemented

- Reduced costs with parallel developments

- Modest Non-Recurring Engineering (NRE) costs

- Low-volume commitment

- Your logic device(s) will not require any additional radiation qualification or screening

- Your product can be packaged in plastic, ceramic, or used as a DIE in a multi-chip module

Why so fast?

With our “sea of gates” design structure and preorganized I/O and power, the logic implementation is done at the final metal layer, allowing the creation of a single custom mask to implement the needed logic function.

Since the connection layer is also the final layer, the silicon wafers are stored at the fabrication plant, at that last step, significantly reducing time to delivery.

Examples of what Rad-Flex™ Logic can do for you:

A logical story, of course…

The robotics division of one of the larger space sector companies wanted to better understand which Apogee Rad-Hard logic devices their lead engineer could best utilize in their most recent design. They asked about our Rad-Flex semi-custom logic process and if it could be used to create a device, that did not exist in the standard logic families, and had been implemented as discrete logic in previous designs.

The function in question is called a 2-bit arbiter, in that between two bits of logic, regardless of what conditions might exist on the inputs, the outputs are guaranteed to be exclusive or (XOR). They desired to optimize the discrete device’s size, weight, and footprint and to have full radiation-hardened specifications.

Our engineering team reviewed the requirements and waveform data, implemented a simulation, and created the mask sets to produce both 30Krad and 300Krad devices. From concept to a device in months, that is remarkable in the radiation-hardened industry.

The tale of too much…

An engineering firm approached us with a critical shortage on a military production design. On their military design was a logic chip, in DIE form. It was not a unique logic chip or in short supply, in packaged form, but the need was for DIE. The standard vendor would only sell an entire wafer boat of DIE, some 125,000 DIE; the need was for 500. The cost was more than $300,000 USD for the boat of wafers.

Their other option was to buy commercial packaged units, dissolve the plastic in solvents, and have the DIE harvested, cleaned, tested, and prepared for mounting. The risk cost and time were staggering.

Neither of those options seemed even remotely appealing to the customer. Then came Rad-Flex™ semi-custom logic. We were able to make the device they needed for much less than the cost of the boat of wafers and without the risk and complications of DIE harvesting.

Start Your Rad-Flex design now!

Join the evolution in rad-hard logic function design and come to market faster and with less cost!

Contact Us to learn what Apogee Semiconductor can do for you.